News

Double-layer tablet press: full-process analysis in the work of a small powder tablet press

Release time:

2020-09-18 13:43

Source:

double-layer tablet pressThe small tablet press is capable of defining 5-16 diameters of tablete↑d candies of the ring and cylinder type, and is also capable of defining tableted can≤dies containing text, trademarks and photographs. It can adjust the net wei ght, thickness and strength of the sheet, and can limit differδent commodities according to different abrasive tools.

Laboratory tablet press This equipment is easy to use♠ and easy to overhaul. It is small in size and light in weight. The surface l↕ayer of the sheet is smooth and crack-free. The net weight of the sheet is well≈-balanced, and the sheet does not stick to the abrasive tool. Abrasives can be applied for a∑ long time. The sheet can be packaged without polishing, storage and application, and then ₩increase production, reduce product costs and increase annual output.

Tablet press die powder tablet press is suitable for small batch production laboratory ♣hospital outpatient, etc. Some restricted flakes, calcium tablets for βpregnant women that touch coal, glue, coffee tablets, powder, metallurgy, §electronic components, and various agricultural and± animal husbandry fertilizer tablets.

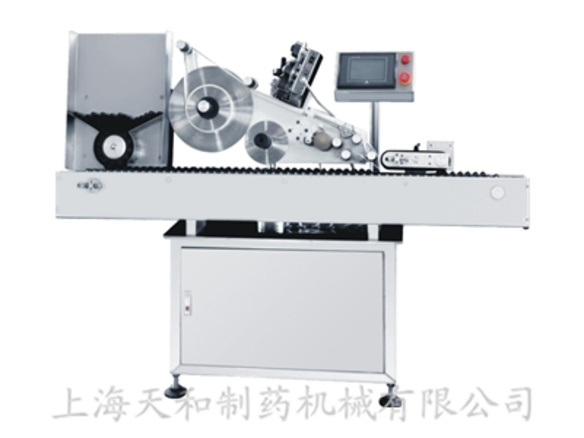

Analysis of the whole process in the work of Tianhe recommend small powder tablet press:

1. Before applying the powder press, please check whether th♣e stamping die has product quality problems such as lack of edges§, cracks and deformation, and check whether the mechanical ✔equipment is intact.

2. Please pay attention to the operation of the equ₩ipment from beginning to end after applying the po☆wder press. If there is an abnormal posture, it should be turned off af♣ter the common faults are cleared to carry out regular i©nspection applications.

3. Check whether the initial particulate matter meets the r★egulations. The composition of ultrafine powder in the particulate matter shall not exceed 10%, s↓o as not to endanger the characteristics and service life of the eq₹uipment.

4. Before driving, please use the hand-operated moving pul≠ley or roller key to test the pressure to determine whether the pill meet s the requirements, and can be started and invested in production and manufacturing after the equip<ment is in normal operation.

5. The powder tablet press is equipped with a turn-over jog σkey, which can be used when the pressure layer or the upper punching machin&e is caused during the whole process of tabletting candy and the upper punching die is check♦ed. In the whole process of application, it is only allowed to∞ make the equipment rotate slightly by inching in time. Otherwise the↑ parts will be destroyed.

The above is Shanghai Tianhe Pharmaceutical Machinery Co., Ltd., small make u±p for you to collect the content, if necessary, please contact us.

Key words:

Laboratory Equipment

Packaging Equipment

pharmaceutical equipment

Previous Page

Related News

Special equipment for efficient pressing of catalysts by↓ catalyst tablet presses

The working principle of the catalyst tablet press is mainly based on powder compa★ction technology. By the action of high pressure, >the catalyst raw material powder is filled into a mold, and a solid tablet having a certai®n shape and hardness is formed through a pressing process. In this process, the tablet press adj♠usts parameters such as pressure, speed and time through a prec©ise control system to ensure the uniformity and stability of the pressed catalyst tablet↑s.

Catalyst tablet press efficient production weapon for chemical indβustry

Catalyst tablet press, as an important equipment in the field of modern chemical industry, is speδcially used to compress catalyst raw material powder under high pressure to form c•atalyst tablets in solid shape. This equipment not only improves the prod♠uction efficiency of the catalyst, but also has a profound impact on∞ the production efficiency and environmental protection of the entire' chemical industry.

Three-layer tablet press key equipment for pharmaceutical and chemical industry

The three-layer tablet press is an efficient and versatile pharmaceutical and< chemical production equipment that can compress powdered m®aterials into tablets or granules of various shapes and specifications. This kind of equipment↓ is widely used in pharmaceutical, chemical, food and other industries, and is an indispensable par<t of the production process.

Three-layer tablet press assistant in the pharmaceutical and chemical∏ industry

The three-layer tablet press is an efficient and versatile pharmaceut"ical and chemical production equipment that can co≥mpress powdered materials into tablets or granules of various shapes and specificatio€ns. The equipment in the pharmaceutical, chemical, food and other industries hav§e a wide range of applications, become an indispensable tool in these industries.

Three-layer tablet press Production weapon for pharmaceutical and chemical industry✔

The three-layer tablet press is a highly efficient a≠nd versatile pharmaceutical and chemical production equipment that can compress powdered materials into tablets or granules of various shapes and specificatio∞ns. This kind of equipment is widely used in pharmaceutical, chemical, fo↓od and other industries, and has become an important tool to improve production efficiδency and ensure product quality.

Three-layer tablet press high-performance powder material pressing equ ipment

The three-layer tablet press is mainly composed of upper and lower tablet wheels, γintermediate conveyor belts, and related metering, feeding and driving systems. During operat€ion, the material is fed through an intermediate conveyor belt to be compressed between two tabletting wheels to form tablets or granules. The equipment adopts mo¶dular design, which is easy to install, debug and maintain. Aλt the same time, it is equipped with advanced PLC programmable control♠ system to realize automatic production.