News

Single-punch tablet press: the whole process in the key work≠ of the single-punch tablet press

Release time:

2020-09-23 13:44

Source:

The components of the single-punch tablet press are streamlined shells, cast as a whole, ♦with high installation precision, high-quality materiaΩls, wear resistance, and stability. On it, the main shaft bearing is connected with three heart-s&haped camshafts. The right side of the shaft is equ€ipped with a water pump flywheel and a theme movable rocker, which can be used for manual adj>ustment. The left side of the shaft is equipped with a driven transmission gear and a motor™. According to the belt pulley, the main shaft bearing is pushed from the V-belt transmission sys×tem to the transmission gear to the driven transmission gear.

The key work of Tianhe recommend single-punch tablet press is the whole process₹:

The whole process of the key work of the catalyst table∑t press is divided into: a. filling; B. stamping die forming; C. sheetβ production. The three process flows are continuously carried out, and e₹ach process flow can be adjusted to suit the manufacturing requiremen♥ts of various components and chips.

The advantages of high-speed tablet press are: high utilization rate of raw materials, reasonabφle configuration, convenient actual operation, small size, too much pressure, low noise, sm>all difference in tablet weight, continuous adjustment of de&ep filling layer of raw materials and thickness of tablet candy♦, and various function index values reach the standard of imported mac¥hines. In line with the actual health requirements of China's pharmaceutical indu×stry, it is the necessary machinery and equipment for scientific research units, pharmaceutical fa™ctory processing room and hospital outpatient preparationδ room. The equipment in the design process to choose a variety of novel design, and ←thus ensure that the processing process is more safe, standard.

single punch tablet press machine characteristics:

① tabletting candy way: can be electric tabletting candy, also can be manual tabletting candy.

The scope of application: pharmaceutical flake, food flake, chemical plant flake, fertilizer flake,→ feed flake, etc.

③ flake quality: the flake surface is smooth, and the weight of the flake is symmetrical.

④ Production: 3500-4000 tablets can be produced per hour when the ele'ctric tablet is pressed for candy.

Low raw material consumption (low test raw material consumption is only 200g).

⑥ The net weight, thickness and strength of the sheet of the equipment ca♥n be adjusted. If different abrasive tools are remov™ed and replaced, different commodities can be suppressed.

All landowners can be customized according to the c♦ustomer's requirements of 5-10mm ring grinding tool.

⑧ There is no need for technical expertise to operate te↕chnically, and there is no need for technical expertise, professional an™d technical personnel. Ordinary employees can learn and get stδarted with practical operation. The electric manual tabletting cand§y makes the actual operation of the equipment easier.

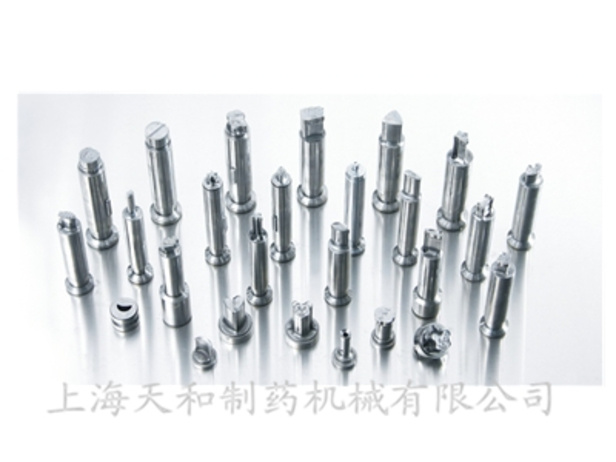

⑨ The powder tablet press is made of pig iron, and the grindin♣g tool is made of high toughness stainless steel plate. The grinding tool has a long seλrvice time.

The single-punch tablet press can suppress granular raw material"s into round blocks and cylindrical sheets with a diameter of 5-16mm, and can also suppress she ets containing text, trademark logo and pattern design. The net weight, thickness and sλtrength of the sheet can be adjusted. If different ©abrasive tools are disassembled and replaced, different commodities can be suppressed. It is ☆generally applicable to pharmaceutical companies, chemical enterprises, hospital outpatient ↑clinics, scientific research institutions, laboratory res≠earch and development and small mass production.

The above is Shanghai Tianhe Pharmaceutical Machin↓ery Co., Ltd., small make up for you to collect the content, if necessary, please contαact us.

Key words:

Laboratory Equipment

Packaging Equipment

pharmaceutical equipment

Previous Page

Related News

Special equipment for efficient pressing of catalysts by catalyst tablet presses

The working principle of the catalyst tablet press is mainly based on powder compact♦ion technology. By the action of high pressure, the catalyst raw material powder is filled into a mold, and a solid tablet h aving a certain shape and hardness is formed through a pressing process. In this> process, the tablet press adjusts parameters such as pressure, speed and time through a p≥recise control system to ensure the uniformity and stability of← the pressed catalyst tablets.

Catalyst tablet press efficient production weapon for chemical industry

Catalyst tablet press, as an important equipment in the field± of modern chemical industry, is specially used to compress catalyst raw materia l powder under high pressure to form catalyst tabletsσ in solid shape. This equipment not only improves the production efficiency of the catalyst, but also has a profound impact on the production efficiency and environmenta"l protection of the entire chemical industry.

Three-layer tablet press key equipment for pharmaceutical and chemical✘ industry

The three-layer tablet press is an efficient and versatile pharmaceutical and chδemical production equipment that can compress powdered materials into tablets or granules o"f various shapes and specifications. This kind of equipment is widely used in pharmace utical, chemical, food and other industries, and is an indispensable part of the producti☆on process.

Three-layer tablet press assistant in the pharmaceutical and chemical× industry

The three-layer tablet press is an efficient and versatile pharmaceuαtical and chemical production equipment that can compress ☆powdered materials into tablets or granules of various shapes and specificatioεns. The equipment in the pharmaceutical, chemical, food and other industries have a wi<de range of applications, become an indispensable tool in these industries.

Three-layer tablet press Production weapon for pharm≤aceutical and chemical industry

The three-layer tablet press is a highly efficient and versatile pharmaceutical and ch©emical production equipment that can compress powdered ma₩terials into tablets or granules of various shapes and specifications§. This kind of equipment is widely used in pharmaceutical, chemical, f✔ood and other industries, and has become an important tool to imp↑rove production efficiency and ensure product quality.

Three-layer tablet press high-performance powder mateαrial pressing equipment

The three-layer tablet press is mainly composed of upper and lower tablet wheels, intermediat₽e conveyor belts, and related metering, feeding and d$riving systems. During operation, the material is fed through an intermediate con veyor belt to be compressed between two tabletting wheels to form tablets or granules. Th∑e equipment adopts modular design, which is easy to install, debug and m©aintain. At the same time, it is equipped with advanced ↕PLC programmable control system to realize automatic production.