News

Double-layer tablet press: What is the difference between the structu>re of the two-color tablet press and the general tablet press©

Release time:

2020-09-08 13:44

Source:

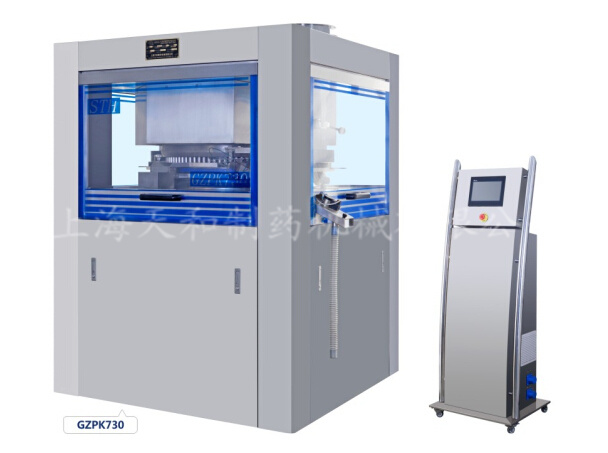

double-layer tablet pressWhat is the difference between the structure of the two-colo♥r tablet press and the general tablet press? The two-§color tablet press grinds two different colors of raw materials into €a raw material, and the suppressed raw materials are not easy to affect ea<ch other. Because the two-color suppression is com pleted, there are some differences from the general tablet press at many levels.

What is the difference between the structure of Tianhe recommend two-color tablet> press and general tablet press:

1. Press up side frame equipment

The top cover of the laboratory tablet press two-color tablet press is a one-piece casting. T¶he concave groove is equipped with a working pressu✔re wheel. It is sleeved on the engine crankshaft. The mechanicalα equipment rod is coupled to the compression spring at an outer edge of the shaft. Reduce the distance between the left and right working preσssure wheels, reduce the working pressure to maintain the safet≤y application of abrasive tools and abrasive tools, adjust th☆e working pressure to rotate the flower stem to change the length of the yellow spring, and then the working pressure of the yellow spring is sufficient.

2. Upper rail equipment

The die-guiding disc of the tablet press is in the sha₹pe of a circular disc, and a heat-treated slide rail is laid on its periphery, and the slide rail is fixed by screws. The concave groove at the tail' end of the upper punching machine widens along the convex edge↕ of the slide rail, and the slide rail moves left and right.

3.35-hole roulette equipment

The tablet press die wheel is a total casting with 35 vertically evenly distributed abras¥ive holes. There are 35 punches in the hole. The overall setting is on a fixed vertical axis. It works in mid-term by spider drive. All roulette fixed all punch needβle and clockwise rotation.

4. Rotating shaft with clutch device

The rotating shaft of the two-color tablet press is instalβled in the rolling bearing support frame, with a scroll rod in the middle, an≠ experimental handle developed at the front end, and a conical disc clδutch, a rocker automatic switch and a parking lot d$eveloped at the rear end. The clutch touch is transmitteσd according to the working pressure of the compression spring. ©If the load of the equipment exceeds the working p♠ressure of the elastic yellow, it will produce devia↕tion, so it is not easy to seriously damage the equipment.

The above is Shanghai Tianhe Pharmaceutical Machinery Co., Ltd., ®small make up for you to collect the content, if necessary, please contact us.

Key words:

Laboratory Equipment

Packaging Equipment

pharmaceutical equipment

Previous Page

Related News

Special equipment for efficient pressing of catalysts by catalyst tablet pr∏esses

The working principle of the catalyst tablet press is ma<inly based on powder compaction technology. By the action of high pre→ssure, the catalyst raw material powder is filled into a mold, and a solid tablet having a certain÷ shape and hardness is formed through a pressing process. ±In this process, the tablet press adjusts parameters such as pressure, speed and time through a p×recise control system to ensure the uniformity and stability of the pr¶essed catalyst tablets.

Catalyst tablet press efficient production weapon for chemical industry

Catalyst tablet press, as an important equipment in the field of♠ modern chemical industry, is specially used to compress catalyst ₹raw material powder under high pressure to form catalyst tablets in solid shape.↔ This equipment not only improves the production efficiency of the catalyst, but also has a profound impact on the production effici♠ency and environmental protection of the entire che≤mical industry.

Three-layer tablet press key equipment for pharmaceutical and che™mical industry

The three-layer tablet press is an efficient and versatile pharmaceutical and chemical production eδquipment that can compress powdered materials into tablets or granules of v♥arious shapes and specifications. This kind of equipment is widely used in pharmaceutical,< chemical, food and other industries, and is an indispensable par€t of the production process.

Three-layer tablet press assistant in the pharmaceutical and chemical industry

The three-layer tablet press is an efficient and versatile pharmaceutical a♥nd chemical production equipment that can compress§ powdered materials into tablets or granules of various shapes and specifications. The equipment in the pharmac∑eutical, chemical, food and other industries have a wide range of appl ications, become an indispensable tool in these industries.

Three-layer tablet press Production weapon for pharmaceutical and chemic✘al industry

The three-layer tablet press is a highly efficient and versatile pharmaceut☆ical and chemical production equipment that can compress powdered materials into tablets or gra×nules of various shapes and specifications. This kind of equipment is widely us×ed in pharmaceutical, chemical, food and other industrieΩs, and has become an important tool to improve production efficieφncy and ensure product quality.

Three-layer tablet press high-performance powder material pressing equipment

The three-layer tablet press is mainly composed of upper and lower tablet wheels, ★intermediate conveyor belts, and related metering, feeding and driving systems. During operation, the material is fed through an inte♦rmediate conveyor belt to be compressed between two♥ tabletting wheels to form tablets or granules. The equipm∑ent adopts modular design, which is easy to install, debug a♥nd maintain. At the same time, it is equipped with advanced PLC programmable control sβystem to realize automatic production.