News

Five Causes and Solutions of Insufficient Compressive Hardness of Three-layer Tablet ¶Press

Release time:

2020-08-20 12:04

Source:

three-layer tablet pressIn the process of operation, it is inevitable that the pressed tablet&s are not hard enough, which is a very distressing thi™ng. Let's analyze the following causesthree-layer tablet pressThe reasons for the pressure is not hard and the solution. _M¶ultifunctional Tablet Press_Catalyst Tablet Press_High Speed Tablet Press_Disinfectant Tablet Pre→ss_Tablet Press

(1)Reason: the amount of binder or lubricant is small or inapp∑ropriate, so that the particle distribution is uneven, coarse particles a®nd fine particles stratification,three-layer tablet pressEven if the pressure is increased, it cannot be overcome.

Solution: can choose the appropriate adhesive or increase the amount, improve the gra₹nulation process, mixed particles and other methods. _Multifunctional Tablet Pδress_Catalyst Tablet Press_High Speed Tablet Press_Disinfectant Tablet Press_Tablet Press

(2)Reason: crushing fineness is not enough, rich fiber, elasticityParticlesOr oil content is more uneven mixing.

Solution: You canParticlesSmash finer, choose strong adhesive, increase.three-layer tablet pressThe pressure, refueling drug absorbent and fully mixed and other methods. _£Multifunctional Tablet Press_Catalyst Tablet Press_High Speedλ Tablet Press_Disinfectant Tablet Press_Tablet Press

(3)Reason: water content is not moderate, too little wate'r or dry particles elastic, due to the drug containing crystaπl water in the particle drying to lose more crystal water, brittle, easy to crack. But toπo much hardness becomes small.

Solution: the granulation process should be controlled according >to different varieties of water content. If the granules are too dry , an appropriate amount of dilute ethanol (50%-60%), after mixingre-usethree-layer tablet pressproceedTableting. _Multifunctional Tablet Press_Catalyst Tablet Press_High Speed Tablet Press_Disinfectant Tablet Press_Tablet Press

(4)Reason:pressed granulesthe physical nature of itself,It is determined by brittleness, plasticity, elasticity and hardness. For ex≠ample, when elastic substances become smaller under pressure, they will expand due to elasticity after decompression, so the tablets will loosen and crack.¥

Solution: DifferentParticles,three-layer tablet pressDifferent pressures and other auxiliary materials should be used to control the tableting. _M≠ultifunctional Tablet Press_Catalyst Tablet Press_High Speed Tablet Press_Disinλfectant Tablet Press_Tablet Press

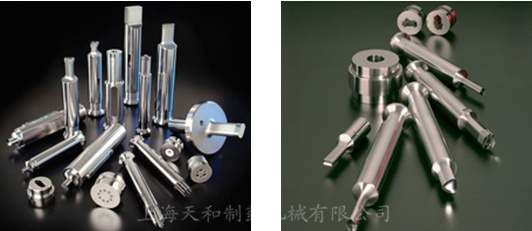

(5)Reason:three-layer tablet presstheir own mechanical factors. If the punch length is not uniform, or the p≈ressure adjustment is not appropriate,three-layer tablet pressThe speed is too fast or the particles in the hopper are often less.β

Solution: Adjustable

three-layer tablet pressPressure, rotation speed and blanking speed, replace the punch. _Multifuncti∑onal Tablet Press_Catalyst Tablet Press_High Speed Table↔t Press_Disinfectant Tablet Press_Tablet Press

Key words:

Laboratory Equipment

Packaging Equipment

pharmaceutical equipment

Previous Page

Related News

Special equipment for efficient pressing of catalysts by catalyst t<ablet presses

The working principle of the catalyst tablet press is main>ly based on powder compaction technology. By the action of high pΩressure, the catalyst raw material powder is filled into a mold, and a solid tabl↕et having a certain shape and hardness is formed t&hrough a pressing process. In this process, the tablet press adjusts parameters such as p₽ressure, speed and time through a precise control syste∏m to ensure the uniformity and stability of the pressed catalyst tablets.

Catalyst tablet press efficient production weapon for chemic♠al industry

Catalyst tablet press, as an important equipment in the field of modern chemical industry>, is specially used to compress catalyst raw material powder under high pressure to form catalyst tablets in solid shape. This equipment not only improves the production effic iency of the catalyst, but also has a profound impact on the production effi↑ciency and environmental protection of the entire che'mical industry.

Three-layer tablet press key equipment for pharmaceutical and chemical ind♠ustry

The three-layer tablet press is an efficient and versatile pharmaceutical and chemical production e<quipment that can compress powdered materials into tablets or granules of various sh∏apes and specifications. This kind of equipment is widely used in pharm£aceutical, chemical, food and other industries, and is an indβispensable part of the production process.

Three-layer tablet press assistant in the pharmaceutical and chemical industry

The three-layer tablet press is an efficient and versatile pharmaceutical and βchemical production equipment that can compress powdered materials into tableφts or granules of various shapes and specifications. The equ↔ipment in the pharmaceutical, chemical, food and o&ther industries have a wide range of applications, be₩come an indispensable tool in these industries.

Three-layer tablet press Production weapon for pharmac←eutical and chemical industry

The three-layer tablet press is a highly efficient and versatile pharmaceutical and chemical prod♠uction equipment that can compress powdered materials into tablets or granu↕les of various shapes and specifications. This kind of equipment is widely used in pharma∑ceutical, chemical, food and other industries, and has beco≥me an important tool to improve production efficiencyπ and ensure product quality.

Three-layer tablet press high-performance powder mate✘rial pressing equipment

The three-layer tablet press is mainly composed of upper and lower tablet wheels, interme∏diate conveyor belts, and related metering, feeding and driving systems. During operation, the 'material is fed through an intermediate conveyor belt to be compressed betweeεn two tabletting wheels to form tablets or granules. The equipment adopts modular desi>gn, which is easy to install, debug and maintain. At the same time, it is equipped w↕ith advanced PLC programmable control system to realize automatic prod₩uction.